Specialty vehicle manufacturers work in an environment where accuracy cannot be compromised. A client may require different storage options in the custom vehicle, while another customer may demand different electrical layouts. As every order is different, specialty vehicle manufacturers have to deal with thousands of configuration combinations.

Managing these product variations manually is difficult. Spreadsheets slow down under complex pricing. Email threads create confusion. Small errors in communication lead to large problems during production.

Without digital support, quoting custom vehicles becomes slow and uncertain. As a result, customers either wait for a long time or move to competitors who provide instant quotes. That is where a custom vehicle configurator solution comes into the picture. It adds structure to the entire sales-to-production cycle. It automates configuration logic, pricing, and documentation creation. It also connects with design and manufacturing systems. This ensures that custom specialty vehicle configuration software works smoothly and reliably.

This article explains how custom vehicle configurator software supports specialty vehicle manufacturers by reducing errors, improving quote accuracy, and accelerating the delivery timeline.

Why Customization Is Hard in Specialty Vehicle Manufacturing

This level of customization required in specialty vehicle manufacturing creates pressure on sales and engineering teams. Every added feature affects something else. Keeping track of these dependencies manually is nearly impossible at scale.

Managing Engineering Dependencies

One of the biggest challenges in building specialty vehicles is managing engineering rules. A salesperson may not always understand technical constraints. They might select an option that conflicts with load ratings, component compatibility, or safety standards.

Complex vehicle configuration software solves this by embedding engineering rules into the configurator. If a certain body style does not fit a chosen chassis, the system hides it. If a selected component increases weight, the system adjusts available options automatically. This prevents impossible or unsafe combinations from moving forward.

The software acts like a technical guide that applies engineering logic in real time.

Discover how Cincom CPQ empowers specialty vehicle dealers to elevate their sales process

Handling Complex Pricing

Pricing custom vehicles is difficult. Materials change in cost. Optional equipment carries installation charges. Some features require structural modifications that add labor hours. Manual pricing often leads to undercharging or missed fees.

Custom vehicle configurator centralizes all pricing rules. When a user selects a component, the price updates immediately. Labor, material, and overhead costs are included automatically. Sales teams no longer need to calculate everything by hand. The result is transparent and accurate pricing for customers and stable margins for manufacturers.

How a Custom Vehicle Configurator Works

A custom vehicle configurator as part of the CPQ process replaces outdated catalogs with an interactive interface that shows only relevant choices.

Real-Time Visualization

Modern custom vehicle configurators display 2D or 3D visual models. When the user selects a paint scheme, storage module, or lighting system, the image updates. This visual feedback helps buyers feel confident in their choices. It also reduces misunderstandings and unnecessary to-and-fros later.

Logic-Based Guided Selection

The custom vehicle configurator uses decision logic to guide the user, be it the sales rep or the customer. The guided selling feature of the tool enables the user to configure the product to ensure that it is feasible and compatible. It allows you to select only combinations that are possible while guiding you throughout the configuration process. This helps the user make informed decisions and keeps the configuration technically sound.

Automatic Bill of Materials (BOM) Creation

Once a quote is finished, the custom vehicle configurator generates a detailed Bill of Materials (BOM). Every part, component, and accessory needed for the build appears in the BOM. This reduces manual data entry and prevents mismatches between what is sold and what is produced.

Integration With CAD and ERP

The custom vehicle configurator solution becomes more powerful when it connects to other enterprise systems and creates a smooth flow of accurate and real-time data.

- CAD integration: CAD integration enables the creation of engineering drawings based on the selected product configuration. This reduces repetitive work and ensures customers understand how the final product will look like.

- ERP integration: The finalized configuration flows into the ERP system. Inventory checks, purchase orders, and production schedules update automatically. This end-to-end flow shortens the overall production timeline.

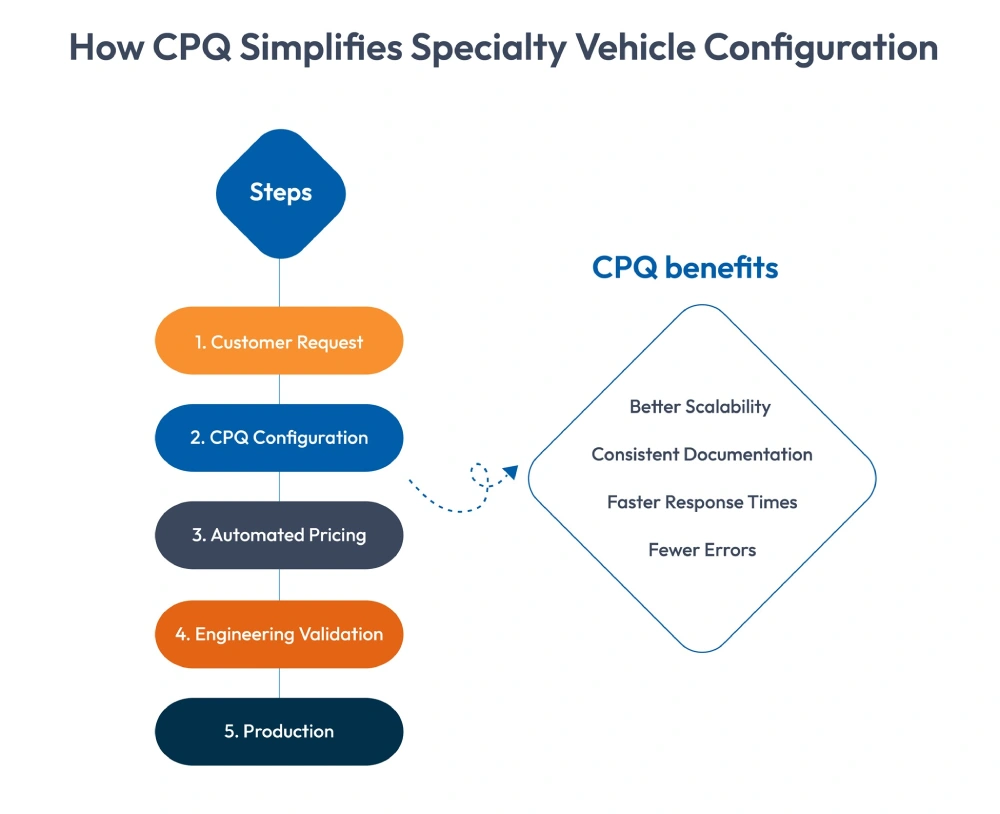

Benefits of CPQ for Specialty Vehicle Manufacturers

Configure Price Quote or CPQ does more than speed up quoting. CPQ simplifies vehicle order processes for enterprises and transforms how they handle complexity and communication.

1. Faster Response Times

With validated configuration rules, sales teams can produce accurate quotes without waiting for engineering checks. This helps manufacturers respond to bids faster than competitors.

2. Fewer Errors

CPQ for specialty vehicle manufacturing blocks incompatible options and prevents invalid configurations from reaching the production stage. This reduces rework and unnecessary to-and-fros between sales and production teams.

3. Better Scalability

CPQ captures product configuration rules and pricing rules, making the process repeatable and efficient. New team members can use this automation to become productive sooner. As a result, organizations can scale their operations without increasing resources or operational costs.

4. Consistent Documentation

Every quote follows the same structure. It includes approved terms, clear descriptions, and accurate pricing. Customers receive professional quotes and proposals every time.

Why Choose Cincom CPQ for Your Specialty Vehicle Business

Cincom CPQ fits well into the workflow of specialty vehicle manufacturers because it handles complex configurations with accuracy. It supports the detailed engineering rules that govern custom-built vehicles, ensuring that every configuration created by the sales team is buildable.

Cincom CPQ also keeps the quoting process fast and accurate, so sales teams can create complete and validated quotes in minutes. This helps manufacturers respond to customer requests and RFPs much sooner.

Pricing accuracy is another advantage. Cincom CPQ updates the price as each option is selected. This reduces the chance of underpricing a complex build and protects overall margins without slowing down the workflow.

Built-in 2D and 3D product visualization generate accurate representations of the final product. This helps customers understand what they are ordering and reduces the chance of design-related misunderstandings.

Cincom CPQ also connects with the tools manufacturers already use, such as CRM, ERP, CAD, and PLM systems. This integration removes manual steps and keeps sales and engineering aligned.

Discover how Fassi Gru, a global leader in crane manufacturing, streamlined workflows and enhanced supply chain efficiency by implementing Cincom CPQ. They were able to achieve efficient production planning, optimized dealer operations, and improved raw material requirements planning.

Conclusion

The level of customization that customers demand in the specialty vehicle manufacturing sector puts immense pressure on the sales and engineering teams, especially when they rely on manual tools and processes.

CPQ steps in as the system that keeps everything steady when the work becomes complicated. It removes guesswork from configuration. It keeps pricing accurate and consistent. It prevents engineering bottlenecks that slow down production. Instead of chasing updates through spreadsheets, teams can focus on delivering vehicles that match the customer’s expectations.

Sales teams can quote confidently. Engineering teams receive clear information. The result is simple: more wins, fewer errors, and a smoother path from quote to cash.

FAQs

1. How does CPQ help specialty vehicle manufacturers manage complex configurations?

CPQ organizes configuration choices and guides users through approved options. It ensures that every build follows technical rules. This keeps quoting accurate and consistent.

2. Can CPQ handle frequent price changes in materials and components?

Yes. Pricing is updated in real-time as per the final product configuration made in the system. Every new quote reflects the latest cost information without manual checks.

3. Is a custom vehicle configurator useful for customers or only for internal teams?

It benefits both. Customers see clear options and pricing. Internal teams work with accurate data and structured choices.

4. Does CPQ help reduce quoting time for high-variation or custom builds?

Yes. CPQ builds quotes in minutes even with heavy customization. It manages variations without slowing teams down.