How CPQ Is Transforming Manufacturing Industry

Quoting and selling complex, configurable products has never been easy for manufacturers. When reps rely on spreadsheets, emails, and outdated tools, mistakes creep in, approvals slow down, and customers wait longer than they should.

CPQ software changes that reality. It brings structure and speed to configuration, standardizes pricing, and keeps data flowing smoothly between systems like ERP and CRM, so teams can focus on selling, not troubleshooting.

And manufacturers are catching on fast.

A recent Revalize report shows that the global CPQ market in manufacturing is expected to grow from USD 3.28 billion in 2025 to USD 7.11 billion by 2034, at a healthy CAGR of 8.97%.

In other words, more manufacturers now recognize that CPQ isn’t just a tool; it’s a competitive advantage.

This blog walks you through real customer success stories that show how manufacturers improved speed, accuracy, and customer experience with CPQ.

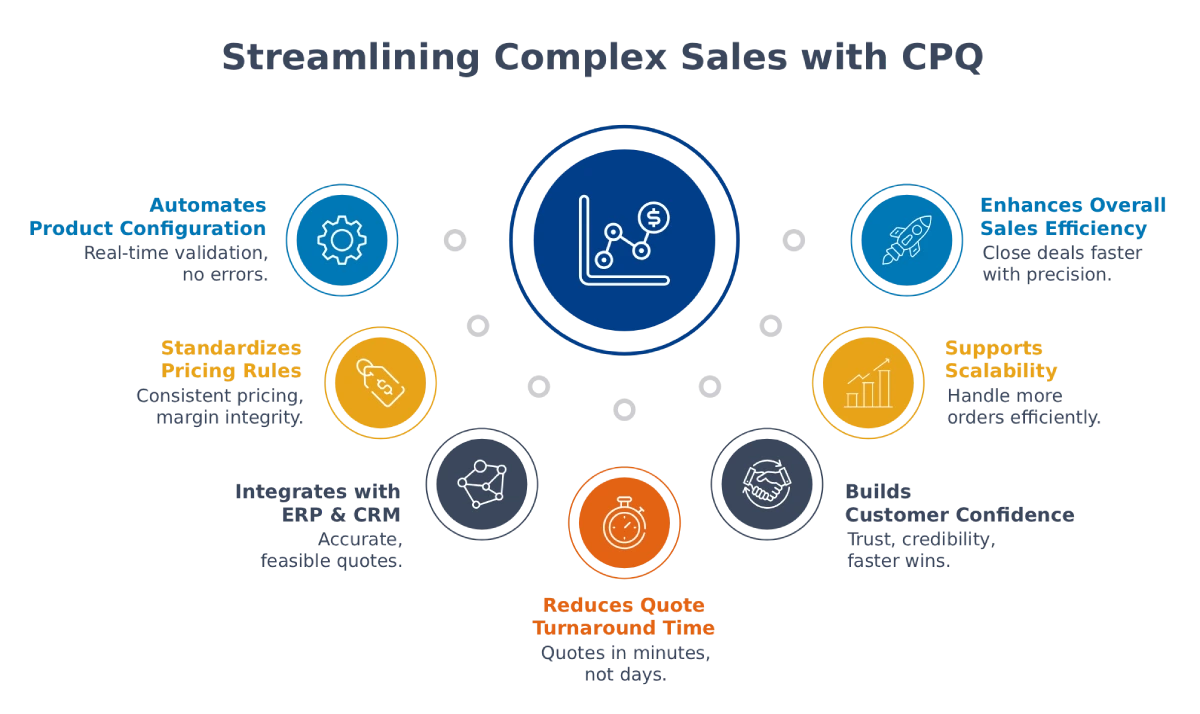

The Role of CPQ in Streamlining Complex Sales Processes

Before diving into the stories, here’s a quick refresher on what CPQ brings to the table:

1. Real-Time Product Configuration

No more guessing or looking for engineers to validate configurations.

CPQ flags incompatible options and suggests valid alternatives on the spot.

2. Consistent, Error-Free Pricing

Pricing logic stays standardized across teams and regions.

Margins stay intact, and errors stay out.

3. Seamless ERP + CRM Integration

When CPQ integrates with ERP and CRM, sales teams quote what’s actually buildable — with accurate inventory, cost, and customer data.

4. Faster Turnaround Times

What once took days can now take minutes.

Buyers notice the difference immediately.

5. More Trust, More Wins

Accurate quotes build credibility.

Credibility builds confidence.

Confidence builds closed deals.

6. Scalable Processes

Even as product lines or sales volumes grow, CPQ keeps workflows smooth and manageable.

7. Better Sales Efficiency

CPQ becomes the bridge between sales, pricing, engineering, and manufacturing — keeping everyone aligned.

Drive Profitable Sales with Cincom CPQ: Streamline, Configure, and Close Deals Faster

Success Story #1: Brother Industries Unifies Sales & Manufacturing

As Brother’s industrial machinery business expanded, the disconnect between Salesforce and SAP became a real bottleneck.

The Challenge

- Sales and manufacturing operated in silos.

- Quotes required multiple back-and-forth and manual checks.

- Sales reps relied heavily on internal experts to configure products.

- BOM inaccuracies caused downstream issues.

- Approvals were slow and difficult to track.

The Solution

Brother chose Cincom CPQ to bring structure, speed, and standardization to its quoting process — and to tightly integrate Salesforce and SAP.

The Results

- Sales and manufacturing finally had one shared source of truth.

- Quotes that took hours are now completed in minutes.

- Automated validation eliminated BOM and spec errors.

- Faster approvals meant faster customer responses.

- Product updates and catalog changes became easier to maintain.

The Impact

Unified workflows, cleaner data, faster quotes, and consistent, error-free configurations.

Success Story #2: Helmer Scientific Reduces Quote Time by 88%

Helmer Scientific produces highly configurable medical and laboratory equipment — and quoting manually took too much time.

The Challenge

- Sales reps spent up to 90 minutes creating a single quote.

- Frequent errors meant rework and delays.

- Scaling sales was difficult without adding new hires.

The Solution

Helmer implemented Cincom CPQ, integrated with Microsoft Dynamics CRM and Fourth Shift ERP, to automate configuration and quoting.

The Results

- Quote time dropped from 90 minutes to under 5 minutes.

- Accuracy improved significantly.

- Customer experience improved thanks to guided configuration.

- The company didn’t need additional sales hires to scale.

“Cincom wanted our IT infrastructure upgrade to be as successful as we did. We definitely recommend Cincom to others.”

— Sara Inghamstraw, Director of Sales Operations and Customer Service, Helmer Scientific

The Impact

A streamlined, fast, and highly accurate quoting process that improved both CX and internal efficiency.

Success Story #3: ATC Boosts Dealer Close Rates by 25%

Aluminum Trailer Company manages a network of 75 independent dealers — each with its own quoting methods.

The Challenge

- Inconsistent configurations and pricing across dealers

- Slow quoting processes caused delays for customers

- ATC lacked visibility into dealer activities

- Scaling operations without errors was becoming impossible

The Solution

ATC rolled out Cincom CPQ across all dealers to standardize configuration and quoting.

The Results

- Quote time reduced by 50%

- Order defects dropped by 90%

- Dealers began closing 25% more deals

- Real-time visibility improved forecasting and production planning

The Impact

Dealers became faster, more accurate, and significantly more competitive — with CPQ guiding every quote.

Success Story #4: Spirax Sarco Goes Digital and Reduces Quote Time From Days to Minutes

Spirax Sarco manages thousands of configurable products across global markets. Their dependence on spreadsheets slowed everything down.

The Challenge

- Manual quoting caused delays

- Errors were common and costly

- Scalability was limited

- Complex configurations required frequent expert support

The Solution

The company chose Cincom CPQ to bring digital structure to quoting, pricing, and configuration.

The Results

- Quotes generated in minutes instead of days

- Configurations became error-free

- Sales cycles accelerated

- The digital sales foundation now supports future growth

The Impact

A scalable, digital-first quoting process that supports global operations without slowing them down.

Common Themes and Key Takeaways from These CPQ Success Stories

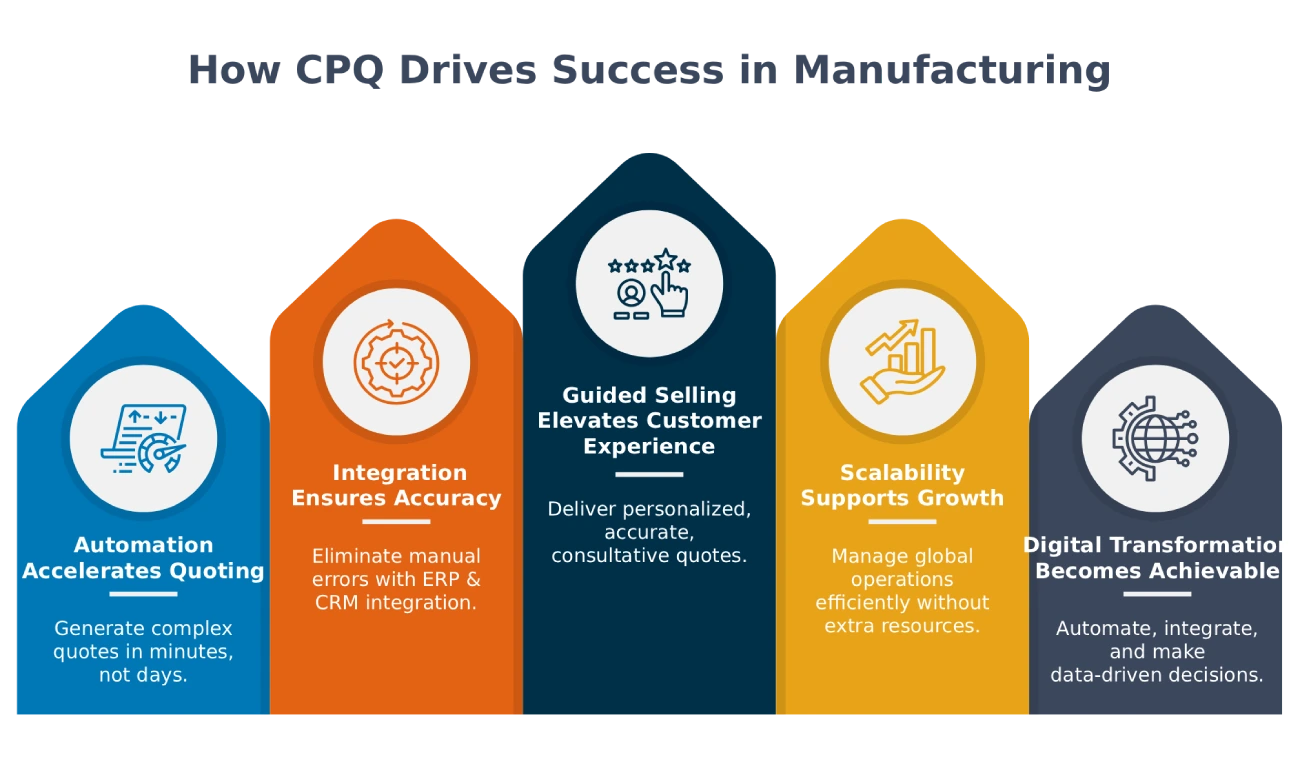

Common Themes from All Success Stories

Across these manufacturers, one message stands out clearly: CPQ is no longer optional. It’s essential.

1. Automation Speeds Up Sales

Quotes move from days → minutes

Reps focus more on selling → less on admin work

2. Integration = Accuracy

ERP and CRM integration reduces rework, errors, and manual entry.

3. Guided Selling Improves Customer Experience

Customers get the right configuration from the beginning.

4. Scalable Sales Processes

Manufacturers can grow — without multiplying their manual workload.

5. Digital Transformation Gets Real

CPQ becomes a foundation for data-driven decisions, efficient workflows, and modern customer experiences.

CPQ as a Catalyst for Growth

These stories show one thing: manufacturers that adopt CPQ see measurable improvements in speed, accuracy, productivity, and customer satisfaction.

Whether your goal is:

- faster quotes,

- higher margins,

- or smoother customer experiences

Cincom CPQ helps manufacturers achieve those outcomes with precision and scalability.

FAQs

1. How does CPQ help industrial equipment manufacturers?

It automates configuration, pricing, and quoting — reducing errors, speeding up quotes, and improving overall sales efficiency.

2. What results do manufacturers typically see with CPQ?

60–70% faster quoting, 90% fewer pricing errors, and higher win rates are common.

3. Can CPQ integrate with ERP and CRM?

Yes. Cincom CPQ integrates with ERP, CRM, and CAD systems for real-time data alignment.

4. How long before CPQ shows ROI?

Most manufacturers see measurable ROI within 6–12 months.

5. What ensures CPQ implementation success?

Clear rules, clean product data, stakeholder buy-in, smooth integrations, and strong user adoption.