Why Are Manufacturers Turning to CPQ?

If you talk to any manufacturing sales team today, one thing becomes obvious: customers expect answers now. Not tomorrow. Not next week. And definitely not “once the engineering team verifies the configuration.”

But when quotes are still handled through spreadsheets, emails, and manual approvals, speed becomes almost impossible—and mistakes become inevitable.

That’s why so many manufacturers are moving toward CPQ systems. Recent studies point out that manufacturers that adopt modern CPQ tools see noticeable improvements in accuracy, cycle times, and how smoothly their CRM and ERP environments work together.

CPQ is simply a smarter way to handle complex product configurations, pricing, and proposal creation, without the back-and-forth chaos.

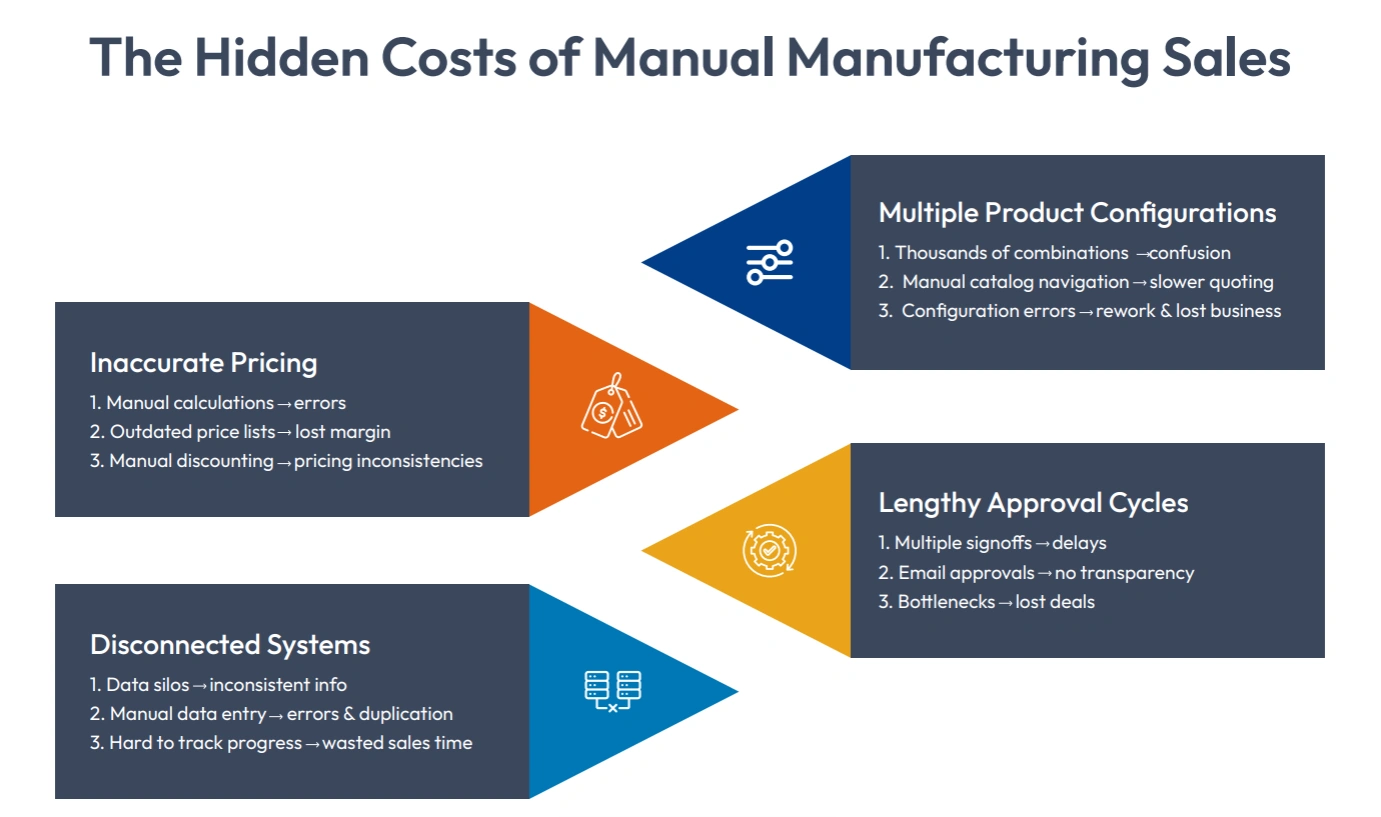

The Challenges of Traditional Manufacturing Sales

Selling in manufacturing has always been a different challenge. Why? Let’s take a look:

1. Multiple Product Combinations

Some manufacturers offer so many product combinations that even the most experienced reps find it difficult to choose the right one. Without automated validation:

- reps rely on gut feelings instead of rules.

- engineering spends time fixing configuration errors.

- customers get frustrated when quotes don’t match what’s actually buildable.

It’s not that reps aren’t skilled; it’s just a system that sets them up to fail.

2. Inaccurate Pricing

Customization, fluctuating material costs, regional discounts, special customer contracts… the list goes on.

When pricing lives in spreadsheets:

- tiny mistakes turn into big margin problems.

- discounting gets inconsistent.

- approval chains stretch for days because everyone wants to “double-check one thing.”

One outdated price list can make an entire quote unreliable.

3. Lengthy Approval Cycles

Most approval processes are slow because reps:

- keeps digging through old versions.

- forwarding endless emails.

- waiting for feedback.

If a key decision-maker is out for the day or the week, everything stalls and the competitor responds faster.

4. Disconnected Systems

If CRM, ERP, and quoting tools don’t sync:

- sales team work with incomplete data.

- operations get inaccurate data.

- customer experience becomes inconsistent.

It’s hard to keep a deal moving when everyone is working with different information.

Are you struggling with manual quotes and disconnected systems? Cincom CPQ for Manufacturing lets your team create accurate, customized quotes in minutes. Explore how Cincom CPQ streamlines the manufacturing sales process.

How Does CPQ Work?

CPQ centralizes all product, pricing, and customer rules. With CPQ, reps can:

- configure products without worrying about compatibility,

- see pricing update instantly based on rules and costs, and

- generate polished, accurate quotes in minutes.

With automation, CPQ eliminates the need for manual re-work and consequent errors.

Stop spending hours on manual quotes with Cincom CPQ.

The Core Benefits of CPQ

Implementing CPQ has a measurable impact across the sales organization. Some of the most valuable benefits include:

1. Faster Quote Generation

- Complex configurations take minutes—not days.

- Guided selling removes guesswork for reps.

- Faster responses lead to better customer experiences and more won deals.

2. Fewer Quoting Errors

- Validation rules prevent invalid configurations.

- Automated pricing removes manual mistakes.

- Eliminating errors reduces rework, delays, and margin leakage.

3. Consistent Pricing

- Standardized pricing rules keep quotes uniform across teams and regions.

- Customer-specific discounts are applied automatically.

- Consistent pricing builds credibility and trust.

4. Higher Sales Productivity

- Automates approvals, pricing calculations, and formatting.

- Reps spend more time with customers and less time on admin.

- Teams can achieve more without adding headcounts.

Find out how Cincom CPQ enabled Fassi Cranes to reach new heights with Cincom CPQ.

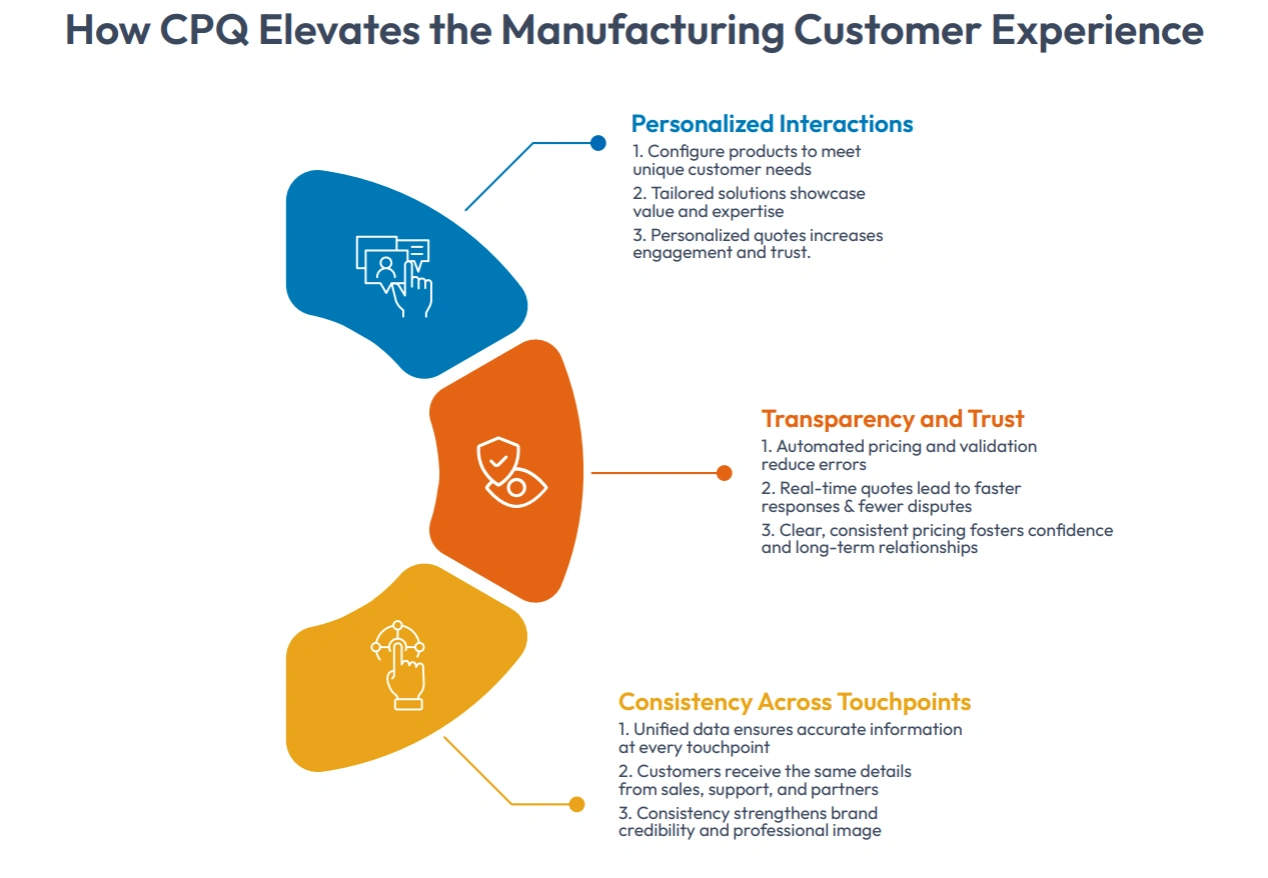

How CPQ Enhances Customer Experience in Manufacturing

While CPQ is often adopted for efficiency, its impact on customer experience is equally powerful.

1. Personalized Buying Experiences

CPQ allows sales reps to build configurations that match each customer’s unique needs. This helps:

- Showcase tailored solutions instead of generic product lists.

- Demonstrate understanding and expertise.

- Provide clarity that improves engagement and trust.

2. Transparency and Reliability

With automated pricing and validation:

- Customers receive accurate quotes the first time.

- Response times drop dramatically.

- Clear and consistent information improves trust.

3. Consistency Across Every Channel

CPQ pulls data from CRM, ERP, and partner tools, ensuring:

- Everyone—sales reps, distributors, support teams—uses the same information.

- Customers get a smooth, consistent experience from start to finish.

- Your brand appears more professional and reliable.

Integrating CPQ with ERP and CRM for End-to-End Efficiency

CPQ becomes even more powerful when it integrates seamlessly with your existing systems.

1. With ERP

ERP integration ensures:

- Quotes reflect real-time inventory, costs, and production capacity.

- Delivery dates and pricing are accurate.

- Any cost or production changes are reflected instantly in quotes.

2. With CRM

CRM integration provides:

- A complete view of customer history and preferences.

- Better personalization, cross-sell, and upsell opportunities.

- More proactive engagement and follow-up.

3. Unified Workflows Across Departments

With CPQ + ERP + CRM working together:

- Sales, engineering, and operations share one source of truth.

- Collaboration becomes easier and faster.

- Sales cycles shorten, and processes become more predictable.

Key Metrics: Measuring Sales Transformation with CPQ

Manufacturers often track CPQ impact using metrics like:

- Quote-to-order conversion rates

- Time taken to generate a quote

- Number of quoting errors avoided

- Revenue per rep

- Customer satisfaction and retention

These KPIs show how CPQ drives not only operational efficiency but also sales performance and customer loyalty.

Want to see your CPQ impact in numbers? Use the CPQ ROI Calculator to measure your potential gains!

Conclusion

With the implementation of CPQ, manufacturers bring much more than just automation to the plate. It brings speed, accuracy, and consistency to the sales process while providing customers with a satisfying experience. CPQ replaces manual, error-prone processes with a modern, integrated quoting workflow that shortens sales cycles, reduces costs, and delivers ROI.

FAQs

1. How does CPQ improve manufacturing sales performance?

CPQ automates configuration, pricing, and quote creation that reduces errors and accelerates the sales cycle.

2. What are the main benefits of CPQ in manufacturing?

Faster quotes, accurate pricing, consistent proposals, higher productivity, and better customer experience.

3. How does CPQ enhance customer experience?

CPQ delivers personalized, transparent, and error-free quotes to the customers that build trust.

4. Can CPQ integrate with ERP and CRM systems?

Yes. Integration ensures that data stays synchronized across the organization.

5. What ROI can manufacturers expect?

Fewer errors, shorter sales cycles, higher conversions, and increased revenue per rep.