How Digital Transformation Is Redefining Manufacturing?

Industry 4.0 is altering global production, and companies need to reevaluate how they promote, produce, and sell products. Moving toward smarter, more connected, and data-driven ecosystems is becoming crucial to sustaining the technology revolution.

CPQ has been the foundation of the industrial sector throughout this paradigm shift. It guarantees precision, faster responses, and improved teamwork throughout the organization. According to current industry research, the manufacturing sector’s digital transformation would increase at a robust CAGR of 17.2%, from USD 874.3 billion in 2025 to USD 4,275.1 billion by 2035.

Digital transformation in manufacturing is all about achieving greater speed, agility, precision, and profitability, and CPQ acts as a catalyst. How? This blog is an answer to this question.

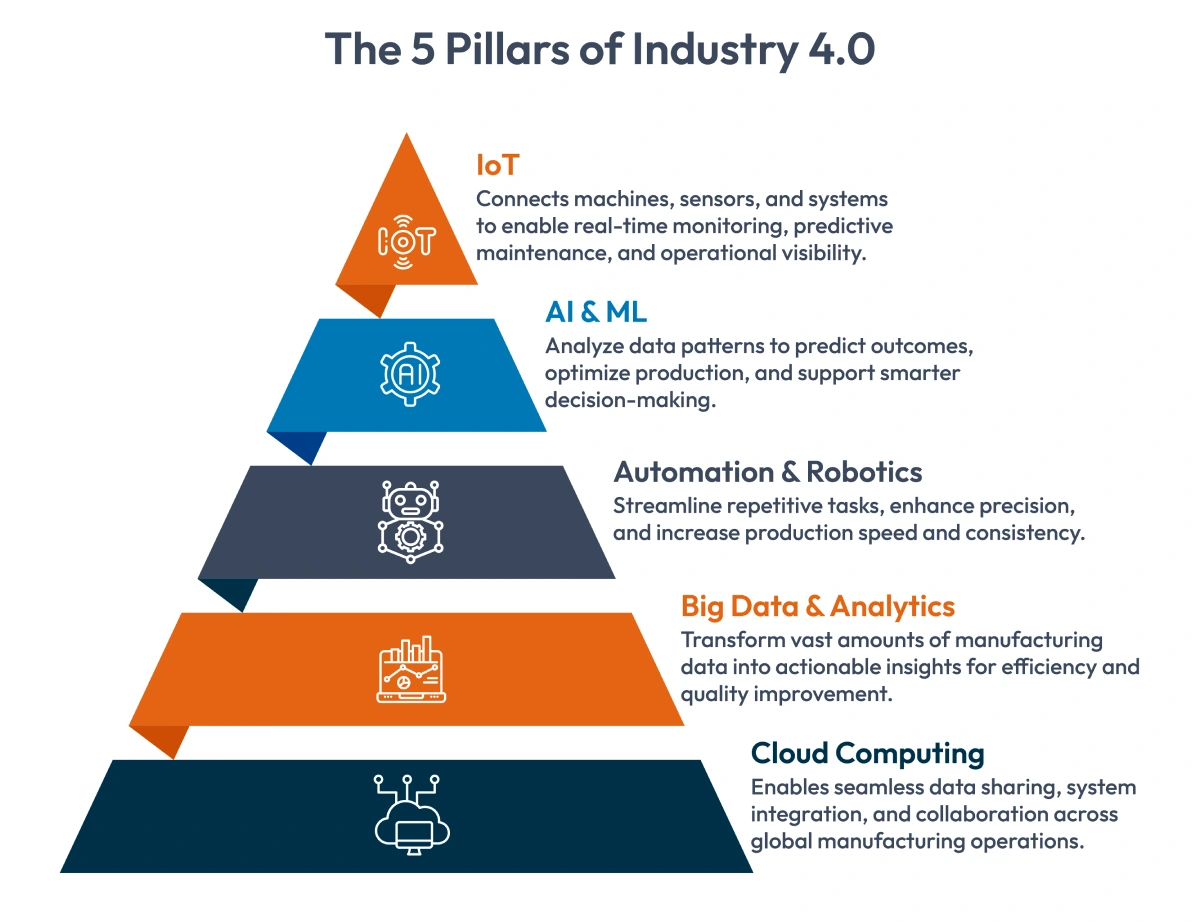

Understanding Industry 4.0 and Its Core Pillars

The shift from traditional workplaces to a more intelligent and interconnected environment is referred to as “industry 4.0,” or the fourth industrial revolution. It integrates digital and physical manufacturing technology such as automation and real-time data that affect every decision and operation. This speeds up production, lowers mistake rates, and increases customer satisfaction for manufacturers.

Here are the core pillars that define Industry 4.0:

1. The Internet of Things

- connects devices, sensors, and machinery across the facility.

- permits predictive maintenance and real-time monitoring.

- enhances production step visibility and control.

2. Machine learning (ML) and artificial intelligence (AI)

- finds trends and forecasts equipment failures by analyzing vast data sets.

- facilitates rapid decision-making and production schedule optimization.

3. Robotics and Automation

- minimizes human mistakes by automating repeated operations.

- increases manufacturing speed, accuracy, and consistency.

- increases flexibility of industrial processes.

4. Advanced Analytics & Big Data

- processes information from suppliers, customers, and machines.

- provides information to predict demand, enhance quality, and manage supply chains.

5. Cloud-based computing

- provides a scalable framework for data exchange and system interaction.

- guarantees central access to precise, up-to-date information and worldwide visibility.

The Connection Between CPQ and Digital Transformation in Manufacturing

CPQ enables manufacturers to manage product complexity, automate sales processes, and guarantee that every quotation accurately represents engineering and pricing data, which links front-end sales with back-end manufacturing.

Here’s how CPQ promotes digitization throughout the manufacturing value chain:

1. Smart Product Configuration

- enables complex products to be configured quickly.

- configurations are guaranteed to be valid and manufacturable by built-in rules.

- minimizes engineering delays and rework.

2. Accurate and Real-Time Pricing

- makes use of current cost, discount, and margin information.

- guarantees precise and uniform pricing across all channels.

- readily adjusts to changes in the market or in prices.

3. Automated Quote and Proposal Generation

- generates professional, error-free quotations automatically.

- increases accuracy and accelerates response times.

- lessens the amount of manual labor in sales.

4. Smooth Data Transmission Between Systems

- connects to CAD, ERP, CRM, and PLM.

- guarantees that authorized quotations are sent straight to production.

- gives production teams comprehensive price and configuration information.

Why Do Manufacturers Need CPQ in the Era of Industry 4.0?

Traditional quoting is unable to meet the requirements of digital transformation, which call for speed, flexibility, and accuracy. To facilitate real-time collaboration and faster, more intelligent quotation, CPQ links sales, engineering, and production.

Here’s why CPQ is crucial for contemporary manufacturers.

1. Faster Time-to-Quote

- automate quote generation and reduces turnaround time.

- sales teams can respond quickly and close more deals.

2. Reduced Human Error

- accurate, compatible configurations and pricing are guaranteed by built-in regulations.

- reduces expensive errors and rework.

3. Customization Driven by the Customer

- makes it possible to see product combinations in real time.

- encourages a more engaging and customized buying process.

4. Smooth Integration with Digital Systems

- connects to CAD, ERP, CRM, PLM, and IoT.

- closely links manufacturing operations to sales inputs.

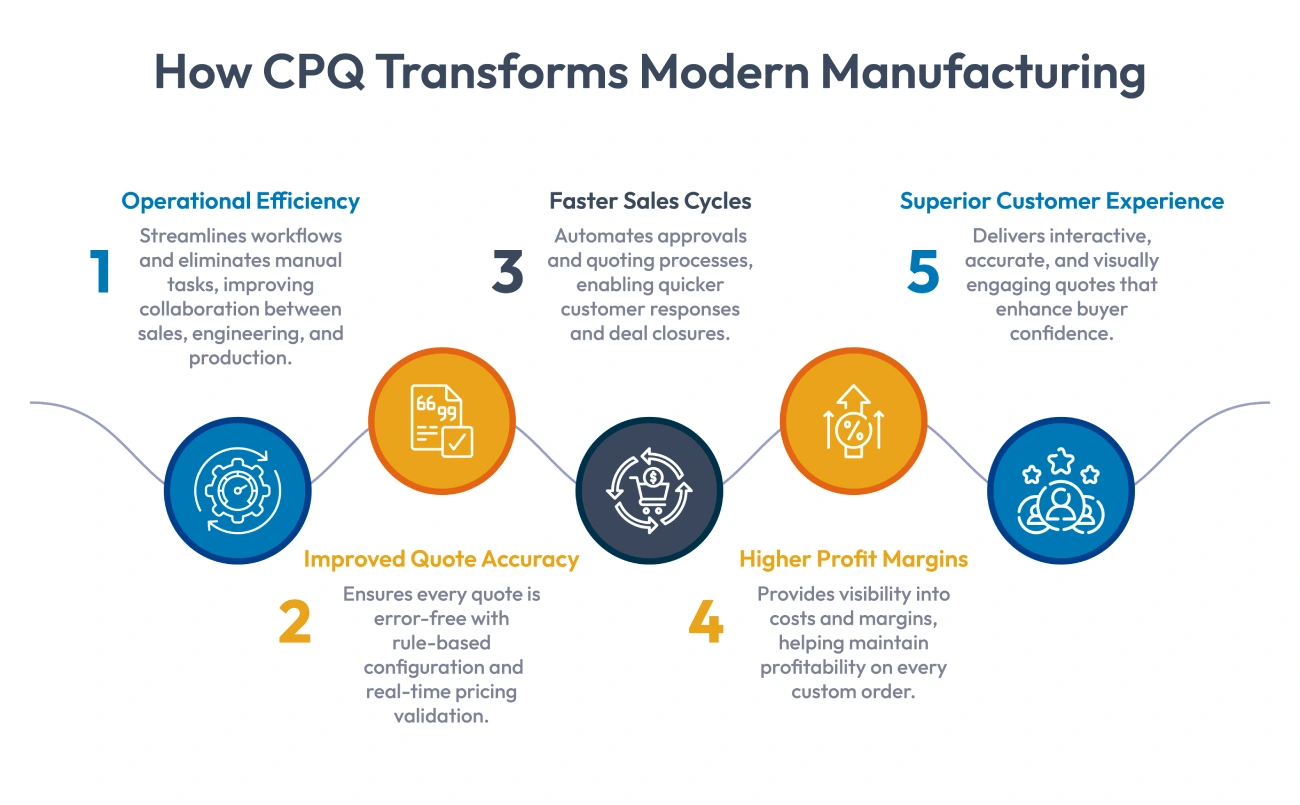

Key Benefits of CPQ for Smart Manufacturing

Manufacturers may improve productivity, accuracy, and client engagement by modernizing their selling and quoting operations with the aid of CPQ.

1. Operational Efficiency

- eliminates repetitive manual tasks.

- centralizes configuration, pricing, and product information.

- decreases rework and enhances teamwork.

2. Increased Accuracy of Quotes

- applies price and product guidelines to each quote.

- shows approved discounts, updated pricing, and eligible configurations.

- minimizes expensive mistakes and misquotes.

3. Quicker Sales Cycles

- makes use of templates, guided selling, and automated approvals.

- reduces the response time for quotes.

4. Increased Profit Margins

- provides visibility into costs and margins in real time.

- reduces underquoting and encourages profitable pricing.

5. Better Client Experience

- provides precise, interactive quotations.

- makes 3D visualization possible for quicker, more confident decision-making.

CPQ + ERP + IoT: Building a Connected Manufacturing Ecosystem

The following stage of digital transformation emphasizes full connectivity. CPQ acts as a bridge between sales and operations, guaranteeing that all quotes are based on real-time information. CPQ links the whole industrial value chain when combined with ERP, IoT, and PLM/CAD:

1. CPQ and ERP

- synchronizes production schedules, inventories, and prices.

- guarantees that quotations are both profitable and feasible.

2. CPQ and IoT

- uses real-time sensor and machine data.

- enables proactive service options, performance-based pricing, and predictive maintenance.

3. CPQ and PLM/CAD

- complies with technical and design guidelines for configurations.

- speeds up delivery and minimizes.

Learn how a global power systems leader cut proposal time from 3–5 days to just 15 minutes with Cincom CPQ.

Download the case study now and find out how automation, guided selling, and seamless integration transformed their quoting process and boosted sales efficiency.

Overcoming CPQ Implementation Challenges

Although CPQ has many advantages, careful planning is necessary for successful implementation. Common challenges consist of:

- Data Integration Complexity: Without a flexible integration strategy, integrating CPQ with outdated ERP, CRM, or PLM systems can be challenging.

- User Adoption: To fully adopt new tools, engineering and sales teams require appropriate training and change management.

- Customization Requirements: Manufacturers frequently need customized workflows and configuration rules to fit their unique procedures.

To address these hurdles, it’s critical to partner with a CPQ provider that offers:

- Proven expertise in manufacturing environments

- An API-first, flexible integration framework

- Scalable, secure deployment options

- Comprehensive onboarding and customer success support

Use the ROI calculator to find out the tangible benefits that you can achieve after implementing Cincom CPQ.

Conclusion

CPQ plays a pivotal role in the digital transformation of the manufacturing industry. It not only brings sales and engineering together but also increases operational efficiency by:

- eliminating silos

- simplifying communication,

- automating pricing, quotation generation, and product configuration.

CPQ becomes an essential component of the digital ecosystem as businesses embrace Industry 4.0, facilitating integrated processes, quicker, more accurate quoting, and an improved customer experience.

FAQs

1. What is Industry 4.0 and how does it relate to CPQ?

Industry 4.0 refers to the digitalization of manufacturing through connected systems. CPQ supports this by connecting sales and production data for faster, more accurate quoting.

2. How does CPQ support digital transformation in manufacturing?

It automates quoting, pricing, and proposal processes—enabling real-time collaboration between sales, engineering, and operations.

3. What are the main benefits of CPQ for Industry 4.0 initiatives?

Speed, accuracy, and connectivity—resulting in higher efficiency and customer satisfaction.

4. Can CPQ integrate with IoT and ERP systems?

Yes. Modern CPQ systems like Cincom CPQ seamlessly integrate with ERP, IoT, and CAD for unified data flow.

5. What challenges do manufacturers face when implementing CPQ?

Integration complexity, change management, and user adoption—but these can be minimized with the right strategy and partner.