The modern manufacturing industry and complexity go hand-in-hand. The demand for accuracy, speed, and personalized configurations is gradually increasing. To meet these customer expectations, manufacturers need to optimize both front-end sales processes and back-end production workflows.

To handle this situation, businesses often adopt an ERP product configurator to manage:

- Backend accuracy

- Product build validation

- Supply-chain alignment

Despite their strengths, ERP configurators do not solve front-end challenges like customer engagement, pricing transparency, or speed of response.

However, when an ERP product configurator integrates with a CPQ system, it helps the manufacturers meet all the modern customer expectations. According to recent research, sales configurator tools aid in real-time configuration with pricing and availability, leading to 40% reduction in quote-to-cash time.

Looking to improve quote speed and accuracy? Discover how Cincom CPQ complements your ERP system.

What is an ERP Product Configurator?

An ERP product configurator is a built-in tool within ERP systems that helps manufacturers manage complexity in product options and configurations. Here’s how it works and where it fits in:

Purpose

- Ensures product rules, options, and constraints are followed during configuration.

- Guarantees that every order placed is technically feasible and manufacturable.

Typical Role in Manufacturing

- Supports production planning by validating configurations against available capacity and resources.

- Automatically generates accurate bills of materials (BOMs) for each product variation.

- Connects with order management so configurations move smoothly from sales to production.

Strengths of an ERP Product Configurator

- Reduces errors by enforcing rules directly in the ERP system configuration.

- Aligns product design with supply chain availability and inventory levels.

- Improves operational efficiency by reducing reliance on manual checks.

- Provides engineers and production teams with confidence that configured products can be built.

Where It Fits in ERP Configuration

- Acts as the “manufacturability gatekeeper” within the larger ERP configuration process.

- Bridges sales orders with backend operations, ensuring consistency across production.

While powerful for backend operations, an ERP product configurator does not provide sales teams with tools for guided selling, dynamic pricing, or automated proposals—gaps that CPQ is designed to fill.

Integrating CPQ with ERP and CRM Systems: A Roadmap for Sales and Operations Leaders

Download our free CPQ integration whitepaper to learn how CPQ + ERP can transform your sales process.

Where ERP Configurators Fall Short?

There’s no doubt that an ERP product configurator plays a pivotal role in ensuring manufacturability. However, it has several limitations when applied to customer-facing processes. They are:

1. Limited Usability for Sales Teams

- Built mainly for engineering and operations, not customer-facing sales workflows.

- Interfaces are often technical, complex, and unintuitive for non-technical users.

- Slows down quote creation due to difficult navigation and configuration steps.

- Increases dependency on engineering or operations for basic configuration help.

- Reduces sales agility when responding to customer queries or pricing requests.

2. No Support for Complex Pricing

- Unable to handle dynamic or rule-based pricing models.

- Lacks support for tiered pricing, volume breaks, or bundled discounts.

- Cannot accommodate customer-specific contracts or negotiated price lists.

- No mechanism for regional or channel-based price variations.

- Forces sales to use spreadsheets or manual approvals, creating errors and delays.

3. Weak Customer Experience

- No guided selling to help reps match customer needs with the right product options.

- Lacks visual configuration or 3D/2D product visualization tools.

- Makes it difficult for reps to communicate value or explain complex options.

- Slows down the buying journey with manual, repetitive questioning.

- Leads to generic, less personalized quoting experiences.

4. Dependency on Engineering Teams

- Sales must wait for engineering approval on non-standard configurations.

- Creates bottlenecks during peak demand or complex deals.

- Slows deal cycles and decreases win probability.

- Engineering teams lose time validating configurations instead of focusing on innovation.

- Causes customer frustration when they can’t receive real-time answers.

5. Risk of Sales–Operations Misalignment

- No automated link between sales selections and production-ready configuration rules.

- Quotes may not reflect what can be manufactured.

- Leads to rework, delayed orders, or last-minute scope changes.

- Reduces customer trust when promised configurations cannot be delivered.

- Makes it difficult to maintain alignment across sales, engineering, and operations.

While an ERP system configuration ensures products can be built, it doesn’t empower sales teams to sell effectively or deliver the modern, customer-centric experience. That’s where CPQ becomes essential.

Why CPQ is Essential for Complex Manufacturing

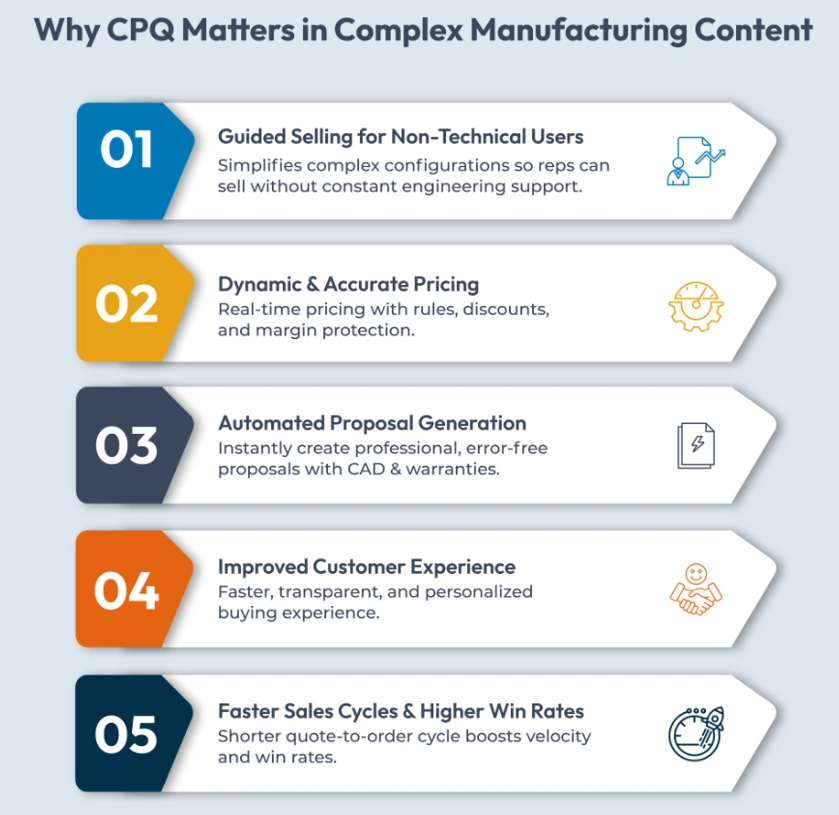

To bridge the gaps left by an ERP product configurator, manufacturers increasingly turn to CPQ solutions. Unlike ERP, CPQ is designed specifically for customer-facing processes and equips sales teams with tools to handle complexity more efficiently.

1. Guided Selling for Non-Technical Users

- Provides step-by-step prompts to simplify complex configurations.

- Ensures only valid, buildable product combinations are selected.

- Reduces dependence on engineering teams for configuration guidance.

- Enables new or non-technical sales reps to sell confidently.

- Minimizes errors caused by manual interpretation of product rules.

2. Dynamic and Accurate Pricing

- Applies real-time pricing rules based on product choices.

- Automatically includes discounts, markups, promotions, and contract pricing.

- Supports region-, channel-, and customer-specific pricing variations.

- Eliminates reliance on manual spreadsheets and outdated price lists.

- Ensures every quote is both accurate and profit-protected.

3. Automated Proposal and Quotation Generation

- Generates professional proposals instantly from approved configuration data.

- Auto-populates technical specifications, compliance details, and warranty info.

- Can attach CAD drawings or product illustrations directly into proposals.

- Ensures all documentation is consistent and error-free.

- Reduces time spent manually assembling proposal packages.

4. Improved Customer Experience

- Enables lightning-fast quote turnaround times.

- Provides personalized recommendations based on customer needs.

- Offers transparency in pricing, options, and delivery timelines.

- Reduces back-and-forth communication delays.

- Builds trust with customers through accuracy and professionalism.

5. Faster Sales Cycles and Higher Win Rates

- Eliminates bottlenecks caused by pricing approvals and configuration checks.

- Reduces rework and quote revisions, speeding up deal closure.

- Helps reps respond faster than competitors during the buying window.

- Strengthens proposal quality, improving win probability.

- Shortens the overall quote-to-order cycle for consistent sales acceleration.

CPQ complements ERP by covering the front-end sales and quoting processes, ensuring manufacturers can deliver both operational efficiency and customer-centric agility.

Real-World Example

From 2 Days to 2 Minutes: The Power of Cincom CPQ

Imagine cutting order entry time from two days to just two minutes. That’s exactly what one global manufacturer achieved with Cincom CPQ. By building a “field-to-factory bridge” and integrating seamlessly with SAP, they now process 1,000+ orders daily, slash manual workload in half, and deliver faster, more accurate results to customers.

Get the inside story on how Cincom CPQ turned complexity into efficiency. Read the full success story!

Benefits of Integrating CPQ with ERP

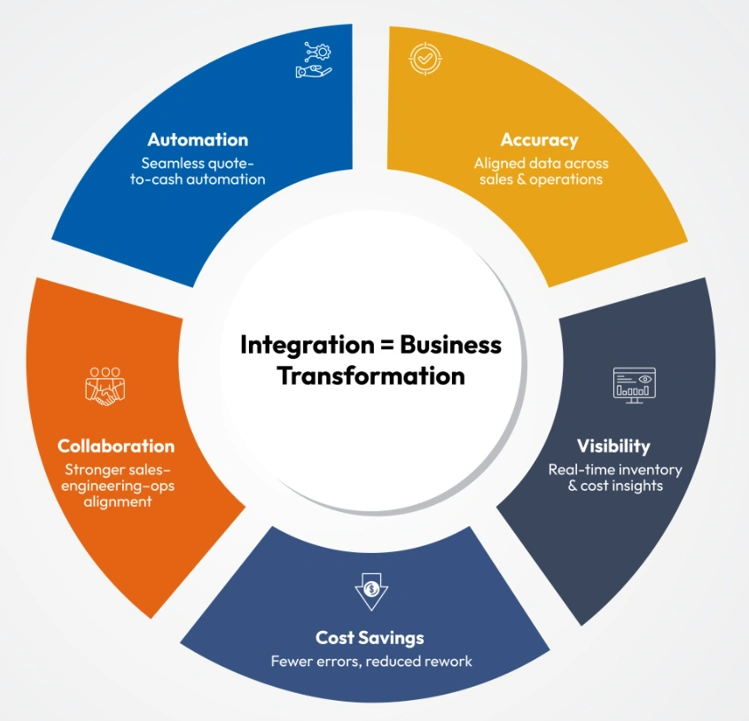

While CPQ and ERP serve different purposes, their real power emerges when the two systems are integrated. Let’s find out the business benefits of this integration:

1. End-to-End Automation

- Sales orders from CPQ flow directly into ERP for production.

- Eliminates manual data entry and reduces administrative effort.

- Speeds up the quote-to-cash process.

- Ensures smoother transitions from sales to manufacturing.

2. Data Accuracy and Consistency

- Syncs product, pricing, and configuration data between CPQ and ERP.

- Prevents sales from quoting non-manufacturable options.

- Strengthens collaboration across sales, engineering, and operations.

- Reduces discrepancies caused by outdated or mismatched data.

3. Real-Time Visibility

- Provides sales teams with up-to-date inventory, cost, and lead-time information.

- Enables accurate delivery commitments.

- Improves customer communication with real-time insights.

- Helps reps make informed decisions during quoting.

4. Reduced Errors and Costs

- Removes manual handoffs that often cause mistakes.

- Reduces rework, production delays, and order revisions.

- Improves order accuracy across the entire workflow.

- Lowers operational costs linked to incorrect quotes.

Making the Right Investment for Configuration Success

When you invest in an ERP product configurator, you ensure every order aligns with production rules, inventory, and supply chain needs. It serves as an operational backbone of the business organization.

However, when it comes to sales-facing agility, CPQ is the one to go for. It brings guided selling, real-time pricing, and automated proposals to the front end.

Therefore, it is never about choosing between ERP or CPQ but both integrated. CPQ and ERP together, create a seamless end-to-end process that delivers faster quotes, higher accuracy and superior customer experience.

Ready to go beyond your ERP product configurator? Request a personalized Cincom CPQ demo today.

FAQs

1. What’s the difference between an ERP configurator and CPQ?

ERP configurators validate product build rules. CPQ handles guided selling, pricing, and quoting. ERP ensures manufacturability; CPQ improves sales speed and customer experience.

2. Can CPQ replace ERP for configuration?

No. CPQ manages sales-side configuration and pricing, while ERP handles production and fulfillment. They work best together.

3. How does CPQ integrate with existing ERP systems?

Through APIs or connectors that sync product rules, pricing, inventory, and push approved quotes into ERP for production.

4. What are the signs that my ERP configurator isn’t enough?

Slow quotes, frequent engineering approvals, pricing mistakes, or customer delays indicate the need for CPQ.

5. Is CPQ scalable for complex, engineer-to-order manufacturing?

Yes. Modern CPQ can manage complex rules, integrate with CAD/PLM, and generate technical documents for ETO workflows.