The Rise of 3D Configuration in Complex Manufacturing

For manufacturers dealing with complex, highly customizable products, precision isn’t just important. It is the backbone of every sale. A 3D product configurator clearly makes a huge difference in this situation. Sales teams do not need to rely on static spec sheets or back-and-forth clarification with the engineering team. They can visualize product configurations instantly and accurately.

A 3D product configurator brings clarity to the sales process, reduces errors, and enables customers to make fast and confident decisions. According to a recent SaleSqueze article, real-time customization through 3D product configurators can reduce errors and speed up quoting by as much as 70%.

If you want to know what the benefits are of using a 3D product configurator, then this blog is for you.

Understanding 3D Product Configurators

A 3D product configurator is a tool that lets users customize a product digitally while seeing every choice reflected in an interactive 3D model. Whether it’s choosing materials, adjusting dimensions, or adding components, the configurator updates the model instantly and checks every selection against defined rules.

The Ultimate Guide to Visual CPQ: Solving Configuration Complexity in Industrial Manufacturing

What a Modern 3D Configurator Actually Does

- Displays a 3D version of the product as the user customizes it

- Validates rules and compatibility in real time

- Adjusts pricing automatically

- Generates quotes instantly

- Sends accurate data to engineering and production

This takes away the guesswork and gives sales teams something they can rely on—even when products involve thousands of possible combinations.

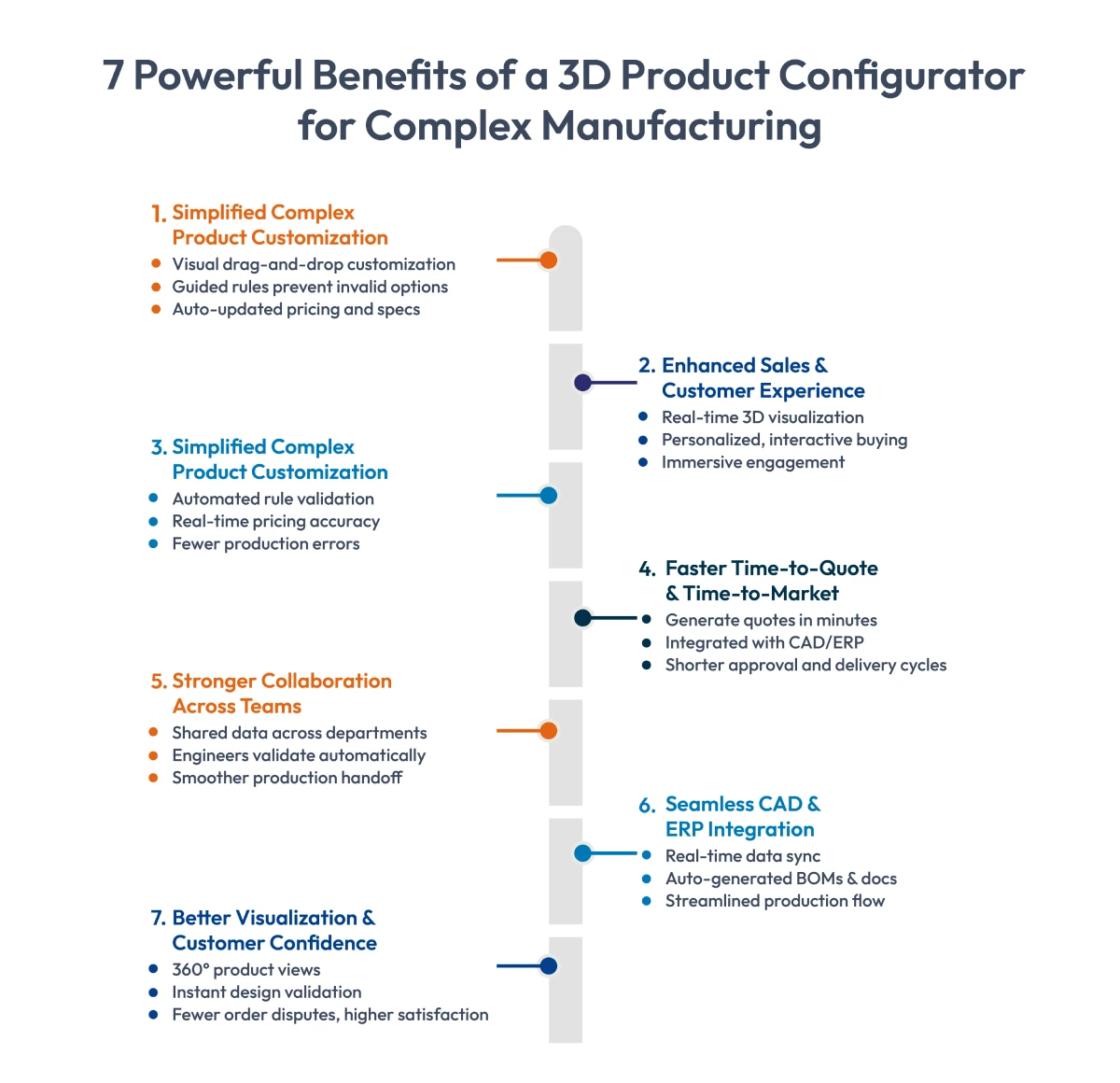

Benefit #1: Simplified Complex Product Customization

Anyone working with configurable products knows the challenges: endless options, engineering constraints, compatibility issues, and the constant risk of selecting something that doesn’t fit. A 3D custom product configurator simplifies all of that.

With guided rules and visual cues, even complex assemblies become easy to understand. Sales reps don’t need to memorize product rules, and customers can configure products confidently without technical expertise.

Why It Works So Well

- Rules are enforced at every step

- Impossible combinations are blocked automatically

- Users clearly see how each customization affects the final product

This streamlines the configuration process and ensures that every quote is based on valid options.

Benefit #2: Enhanced Sales and Customer Experience

A 3D product configurator provides clarity and transparency to customers by providing an immediate visual of what they’re buying, something that static catalog can never do.

Experience Improvements You’ll Notice

- Customers spend more time engaging with the product (not waiting for information)

- They can compare configurations visually

- They understand the impact of upgrades and optional features

- Decisions are made faster because nothing feels ambiguous

With a 3D product configurator software, sales conversation turns into an interactive experience rather than a technical explanation.

Benefit #3: Reduced Quote Errors and Rework

Quoting manually, especially complex products, creates a huge margin for error. A wrong component here, a missing feature there, and suddenly engineering is dealing with rework, incorrect orders, or expensive last-minute fixes.

With a 3D product configuration software, those mistakes drop drastically because:

- Every rule and dependency is already built in

- Pricing updates automatically based on selections

- Only valid configurations can move to the quote stage

This not only cuts down on quoting errors but also minimizes production delays and manufacturing waste.

Benefit #4: Faster Time-to-Quote and Time-to-Market

Speed matters when customers are comparing vendors. A slow quoting process can mean losing a deal entirely.

A 3D product configurator speeds things up by automating the entire configuration-to-quote cycle:

- Sales reps no longer wait for engineering clarifications

- Quotes can be generated within minutes

- CAD data, BOMs, and documentation can be produced automatically

- The handoff between sales and production becomes far more efficient

This time savings helps companies respond faster to opportunities and improve overall time-to-market.

Benefit #5: Stronger Collaboration Between Sales, Engineering, and Production

Miscommunication between teams is one of the major challenges that organizations face. The 3D product configurator is a perfect solution to this problem as it provides teams with a single and accurate version of the product.

How It Improves Cross-Functional Alignment

- Engineering defines the rules

- Sales uses those rules consistently in every quote

- Production receives accurate specs and BOMs

- There are fewer back-and-forth and change requests

This process builds trust among teams and leads to smoother order processing.

Benefit #6: Seamless Integration with CAD and ERP Systems

The ability to integrate with CAD, ERP and CRM systems is a major advantage of modern product visualization software. These integrations ensure that data doesn’t get lost or misinterpreted.

What Integration Enables

- Auto-created CAD drawings for engineering

- Real-time pricing and inventory updates via ERP

- CRM-powered customer insight in the quoting process

- Direct transfer of manufacturing-ready data to production systems

Using a platform like Cincom CPQ brings all these workflows together seamlessly, reducing manual effort and ensuring accuracy at every step.

Benefit #7: Better Visualization and Customer Confidence

With the implementation of a 3D product configurator, customers can visualize the product while it is in the manufacturing stage and can make any changes if required.

Why Visualization Matters

- Customers get a realistic preview of their product

- They see the value of each feature and upgrade

- They feel more confident investing in a customized product

- It reduces post-sale surprises and dissatisfaction

This level of transparency is especially important for expensive, high-precision, engineered-to-order items.

Conclusion

3D product configurators are becoming an absolute mandate for business organizations as the manufacturing industry is gradually shifting towards a more digital-first and customer-driven model. They bring visualization, automation, and accuracy together to help manufacturers make smarter selling decisions.

Are you ready to see the difference?

See how Cincom CPQ’s 3D Configurator simplifies complex product sales.

FAQs

1. What is a 3D product configurator?

A 3D product configurator is a digital tool that lets users customize and visualize complex products in 3D before purchasing, ensuring accuracy and engagement.

2. How does a 3D configurator improve the sales process in manufacturing?

It enables real-time visualization, eliminates quoting errors, and accelerates approvals—leading to a smoother, faster sales cycle.

3. Can 3D configurators integrate with ERP or CAD systems?

Yes. Modern 3D configurators connect with CAD and ERP systems for synchronized design, pricing, and production data.

4. Is a 3D configurator suitable for all types of manufacturers?

While especially beneficial for configurable and engineered-to-order products, it can be adapted to most manufacturing industries.

5. What ROI can manufacturers expect from implementing a 3D configurator?

Manufacturers typically see reduced quote times (up to 90%), fewer order errors, and higher close rates due to improved customer engagement and accuracy.