Industrial equipment manufacturers operate in a world of complex configurations, long sales cycles, and engineering-heavy quoting processes. While customers expect fast, precise quotes, disconnected systems often slow everything down. Sales may configure one version of a product while engineering builds another, and ERP teams may receive incomplete or inaccurate data, leading to rework, delays, and production waste. Several research suggests that companies relying on siloed systems typically achieve only 60–70% first-time quote or order accuracy, while those with integrated CPQ + ERP ecosystems reach 90–95% accuracy.

However, when CPQ connects directly to ERP, manufacturers gain a unified quote-to-order-to-production workflow that avoids data duplication, eliminates human errors, and ensures every team works from a single source of truth. With automated BOMs, real-time pricing, and accurate order data flowing into ERP, manufacturers dramatically improve speed, accuracy, and delivery timelines.

The Disconnect Between Sales and Production in Industrial Equipment Manufacturing

Even the most advanced manufacturers struggle with misalignment when CPQ and ERP operate in silos. The result is a persistent gap between what sales teams promise and what production can realistically deliver. Common challenges include:

- Sales configuring products that engineering can’t build because they’re working with outdated rules, legacy spreadsheets, or incomplete constraint logic.

- Manual re-entry of data into ERP, increasing the risk of errors in part numbers, quantities, pricing, or configuration details.

- Engineering bottlenecks, where teams must re-check or re-validate configurations every time a quote moves into order status.

- Incomplete or inaccurate BOMs reaching production, delaying scheduling, procurement, and manufacturing execution.

A connected ERP product configurator and CPQ system solves these challenges.

Integrating CPQ with ERP and CRM Systems: A Roadmap for Sales and Operations Leaders

What CPQ Does and Why It Needs ERP to Complete the Process?

CPQ software drives the front end of the sales cycle. It empowers sales teams to sell complex, configurable products with speed and accuracy by handling three core functions:

- Configuration: Guides sales through valid product combinations, preventing engineering errors and ensuring every configuration is buildable.

- Pricing: Applies real-time pricing rules, cost data, margin thresholds, and discount logic to deliver accurate, strategically priced quotes.

- Quoting: Produces professional, customer-ready quotes, proposals, and documentation instantly and at scale.

However, CPQ is only one part of the full order-to-production workflow. It doesn’t manage the operational backbone of the business.

When CPQ and ERP work together, manufacturers gain a continuous digital thread, from customer request → configuration → quote → order creation → production execution. This seamless connection eliminates handoff delays, reduces errors, and ensures that every quote is not only accurate but also ready to build.

How CPQ + ERP Integration Streamlines the Quote-to-Order Process

1. Automated Data Transfer

All configuration choices, pricing details, customer information, and commercial terms flow directly from CPQ into ERP. No manual data entry, no copy-paste errors, and no lost information.

2. Real-Time Synchronization

Any change is instantly reflected in both systems. Sales always works with correct data, and operations stays aligned with what was sold.

3. Zero-Touch Order Creation

Once the customer approves the quote, ERP automatically receives everything needed to start production:

- The exact configured product

- Complete and accurate BOM

- Required quantities for each component

- Routing and workflow instructions

- Pricing, discount, and margin details

Eliminating Engineering Bottlenecks with Automated Data Flow

Engineering review is often the biggest source of delays in industrial equipment manufacturing, especially when every quote needs validation.

A CPQ + ERP integration removes this burden by ensuring only buildable, engineering-approved configurations enter the system:

- CPQ applies engineering rules at the point of configuration.

- Invalid combinations are automatically blocked, ensuring sales never sell what engineering can’t build.

- ERP receives complete product data immediately, reducing clarification

- BOMs and routings are generated automatically and accurately, without engineering rework.

This frees engineering teams to focus on high-value design improvements instead of repeatedly checking sales quotes for accuracy.

Ensuring Production Accuracy with Real-Time BOM and Routing Updates

In industrial equipment manufacturing, even small errors in configuration or routing can lead to major losses.

Integrated CPQ-to-ERP data flow eliminates these accuracy risks:

- Material requirements are always precise and up to date.

- Work orders in ERP match the customer’s exact configured product.

- Scheduling and capacity planning reflect real-time part availability.

- Routing instructions automatically align with the chosen configuration.

The result is a highly reliable manufacturing workflow powered by synchronized CPQ and ERP software.

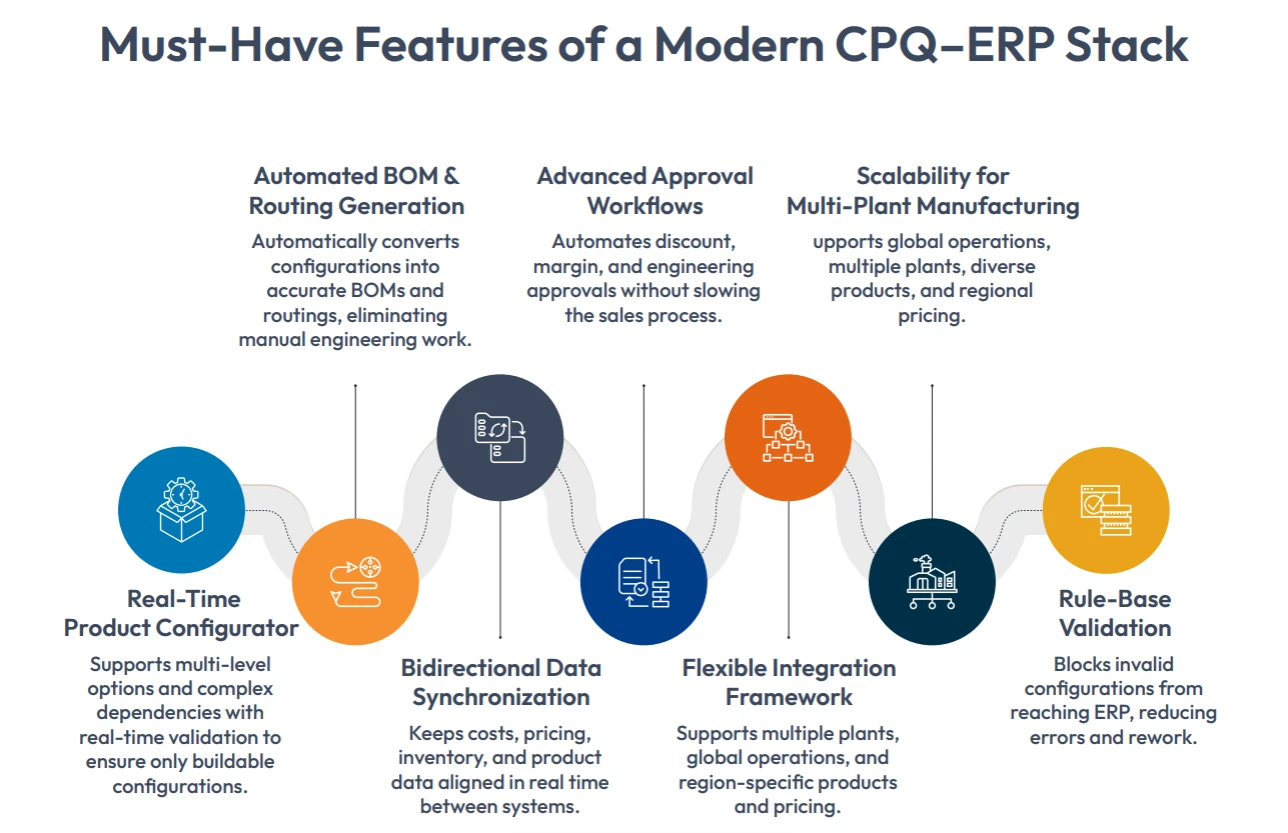

Key Features to Look for in an Integrated CPQ–ERP Stack

1. Real-Time Product Configurator

A robust rules-driven configurator that supports:

- Multi-level and multi-variant configurations

- Complex dependencies and constraints

- Real-time validation to prevent invalid selections

This ensures sales teams configure only manufacturable products from the start.

2. Automated BOM and Routing Generation

The system should automatically convert each configuration into:

- A complete, accurate Bill of Materials

- Fully defined routing steps for production

This eliminates manual engineering work and speeds up order processing.

3. Bidirectional Data Synchronization

Product, pricing, and operational data must stay continuously aligned.

Look for:

- Real-time price and cost updates

- Live inventory and availability information

- Instant synchronization of product updates

This ensures that both sales and operations always work from the same source of truth.

4. Advanced Approval Workflows

Integrated workflows help enforce governance for:

- Discounting and margin thresholds

- Sales manager approval

- Engineering or compliance reviews when required

This prevents bottlenecks while ensuring full control over deals.

5. Flexible Integration Framework

A modern CPQ–ERP stack should support:

- REST APIs

- Pre-built connectors

- Low-code/no-code integration tools

This makes implementation faster and significantly reduces IT effort.

6. Scalability for Multi-Plant and Global Manufacturing

The platform must adapt to expanding operations, supporting:

- Multiple plants and production centers

- Regional or global pricing models

- Diverse product lines and business units

This ensures long-term scalability and operational consistency.

7. Rule-Based Validation at Every Step

Built-in validation rules ensure only buildable configurations reach ERP, helping eliminate:

- Rework

- Production errors

- Engineering back-and-forth

This guarantees production accuracy from the first quote.

Discover how Brother Industries accelerated custom quoting and unified Salesforce with SAP through Cincom CPQ

Get the full story behind their faster estimates, accurate BOMs, and seamless CPQ–ERP integration.

Final Thoughts

The future of industrial equipment manufacturing lies in automation, intelligent workflows, and connected systems. ERP + CPQ integration is the foundation of a modern Q2O2P process.

By removing manual steps, syncing real-time data, and ensuring accuracy from configuration to production, manufacturers achieve:

- Faster delivery timelines

- Lower operational costs

- Higher quote accuracy

- Stronger customer satisfaction

- Reduced engineering workload

This is how manufacturers transition from traditional operations to true Industry 4.0 readiness with CPQ and ERP at the center of the digital thread.

Transform your quote-to-order process with Cincom CPQ. Find out how seamless CPQ–ERP integration eliminates sales–manufacturing disconnects.

FAQs

1. What is the quote-to-order-to-production process in manufacturing?

It refers to the end-to-end workflow starting with customer requirements, moving to configuration and quoting, converting the quote into an order, and finally generating BOMs and work orders for production.

2. Why is CPQ more effective when integrated with ERP?

CPQ ensures accurate configuration and pricing, while ERP manages materials, inventory, scheduling, and production. Together, they create a seamless, error-free workflow.

3. How does CPQ reduce errors in industrial equipment manufacturing?

It applies configuration rules, eliminates invalid selections, automates BOM creation, and reduces manual data entry—all major sources of mistakes.

4. Can CPQ automatically create BOMs and send them to ERP?

Yes. Advanced CPQ systems can automatically generate BOMs, routing instructions, and order details, then push them directly to ERP.

5. What challenges should manufacturers expect during CPQ–ERP integration?

Common challenges include data cleanup, alignment of product models, integration complexity, and change management. With the right framework, these can be managed smoothly.