Industrial equipment manufacturers deal with a sales process that’s anything but simple. Configurations change from customer to customer; pricing varies based on countless factors, and approvals often involve multiple teams. When sales and operations work in disconnected systems, the result is usually delays, manual rework, and unnecessary cost.

Recent research shows that organizations that integrate CPQ with CRM and ERP platforms experience around 20% improvement in operational efficiency. That’s because once CPQ and ERP are connected, every detail from configuration to pricing moves from sales to production. No double entry. No lost information. No surprise when the order hits the shop floor.

Cincom CPQ takes this one step further by integrating smoothly with leading ERP systems, helping manufacturers quote faster, improve accuracy, and accelerate fulfillment.

Understanding CPQ and ERP Systems

CPQ software simplifies the front-end of the sales cycle. It helps teams:

- Configure complex equipment accurately

- Apply the right pricing and discount rules

- Generate error-free quotes quickly

- Ensure that proposals are both feasible and profitable

ERP systems, on the other hand, support the back-end operations of the business — everything from production planning to inventory management and financial tracking.

When CPQ and ERP work together:

- Data flows in both directions without manual effort

- Sales teams gain real-time visibility into inventory, costs, and production schedules

- ERP receives complete, validated configurations and BOMs instantly

- Manual re-entry is eliminated across departments

This alignment makes it easier to move from customer request to production-ready order without delays or errors.

The Common Disconnect Between Sales and Operations

In many industrial equipment companies, sales and operations still work in silos. That’s where most inefficiencies originate. Teams often face:

- Manual re-entry of quotes and configurations

- Orders missing key details

- Limited visibility into inventory, lead times, or capacity

- Slow approval cycles

- Customer frustration caused by delays or inaccuracies

ERP-ready CPQ solves these issues by ensuring that every approved quote becomes a complete, production-ready order automatically.

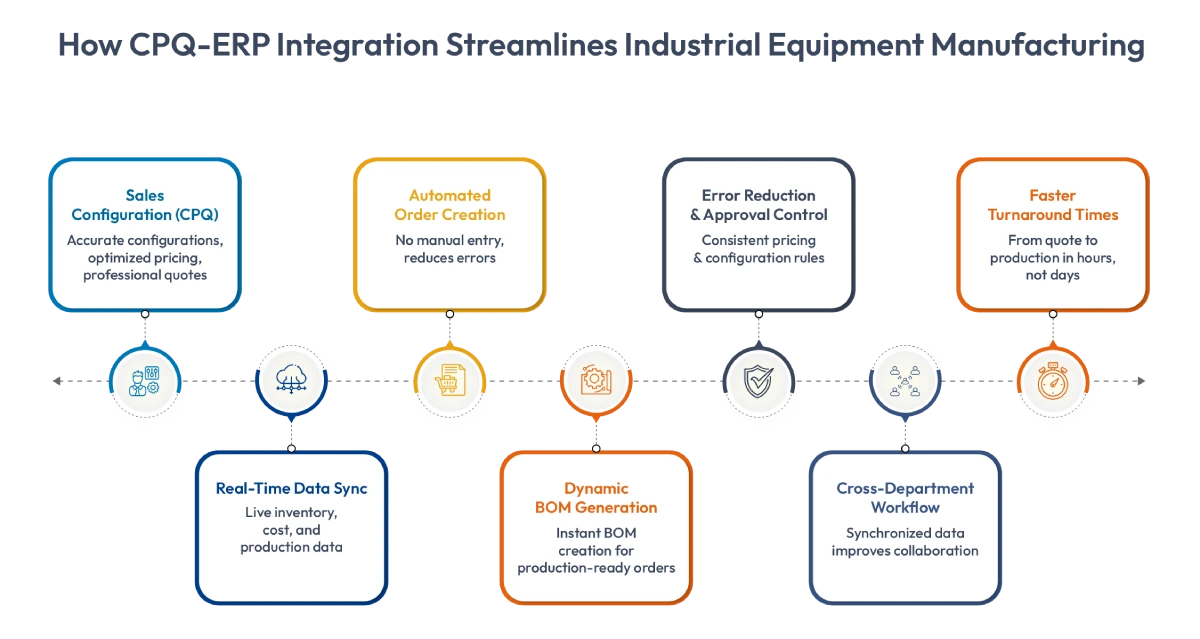

How CPQ-ERP Integration Streamlines Industrial Equipment Manufacturing

Integrating CPQ with ERP creates a unified, automated workflow. Here’s how it improves the sales-to-production cycle:

1. Real-Time Data Synchronization

CPQ uses real-time ERP data — inventory, costs, and capacity — so quotes are always based on accurate information.

2. Automated Order Creation

Once a quote is approved, CPQ automatically creates a corresponding ERP sales order, removing any risk of mismatched data.

3. Dynamic BOM Generation

ERP receives complete configuration details from CPQ, enabling immediate BOM creation and faster engineering kick-off.

4. Error Reduction and Approval Control

Unified rules prevent pricing and configuration mistakes and help enforce compliance.

5. A Connected Workflow Across Departments

Sales, engineering, production, and finance access the same synchronized data, improving teamwork and transparency.

6. Faster Turnaround Times

Manufacturers can move from quote to production in hours instead of days — an advantage that directly boosts responsiveness and competitiveness.

Together, these capabilities ensure CPQ-ERP integration creates a smoother, more dependable manufacturing cycle.

Want to see how this looks in real-world workflows? Request a Cincom CPQ demo to watch the integration in action.

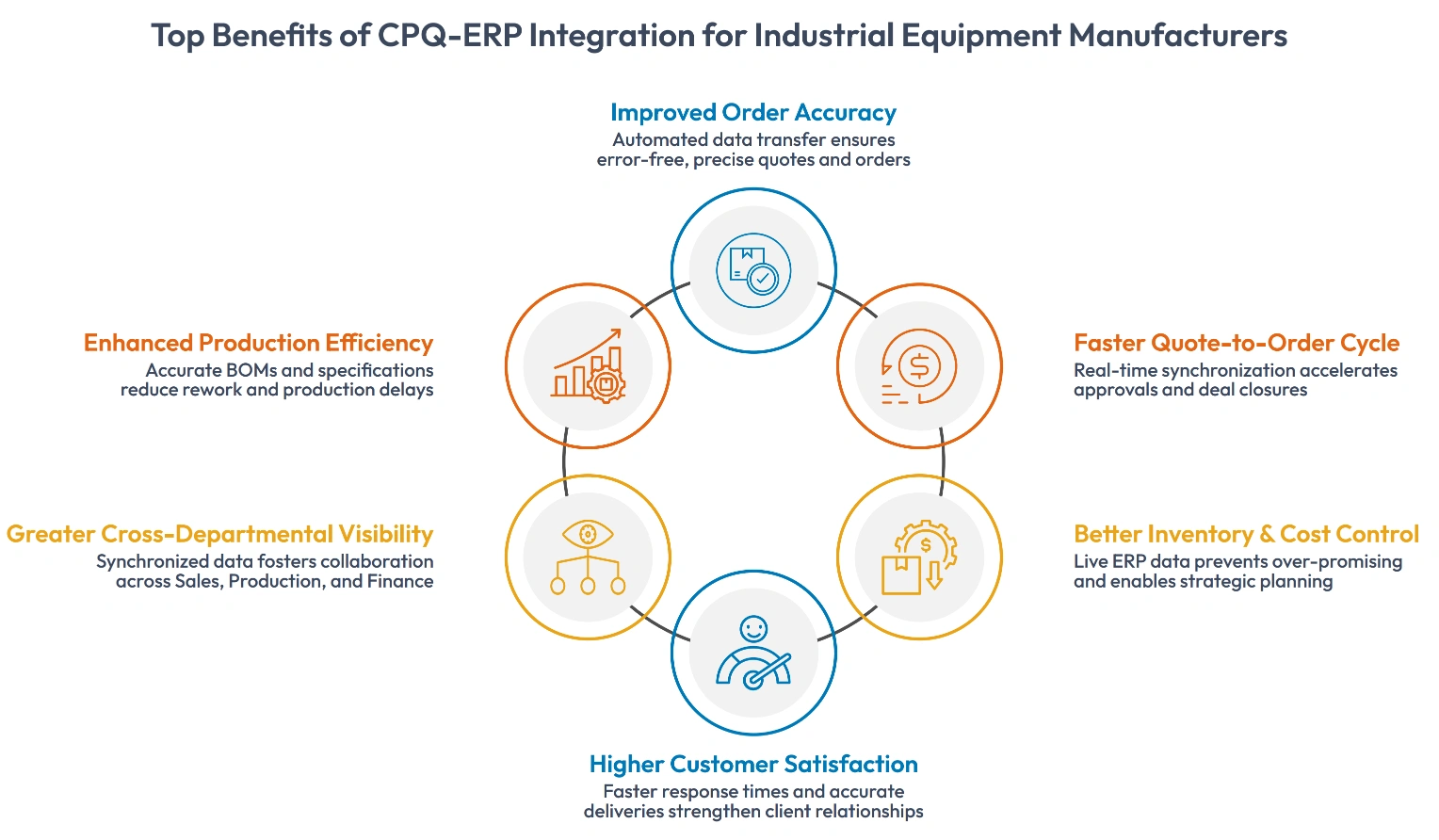

Key Benefits of CPQ-ERP Integration for Industrial Equipment Manufacturers

Manufacturers gain value across every stage of the process:

1. Improved Order Accuracy

With automated data transfer, every order mirrors the approved quote — down to each component and price.

2. Faster Quote-to-Order Cycle

Real-time alignment accelerates production startups, helping sales teams close deals faster.

3. Better Production Efficiency

Accurate BOMs and specifications reduce rework and prevent production bottlenecks.

4. Stronger Inventory and Cost Control

Live ERP data helps sales avoid over-promising and supports better planning.

5. Enhanced Cross-Department Visibility

Shared data gives managers a clearer view of operations and performance.

6. Higher Customer Satisfaction

Accurate quotes and reliable delivery timelines create a more consistent customer experience.

Find out how Cincom CPQ helped Brother Industries overcome the challenges of fragmented systems and synchronized Sales and Manufacturing for efficient custom quotations.

Overcoming Integration Challenges: Best Practices

While integration delivers clear value, the process can be challenging—especially with legacy systems or inconsistent data. The table below outlines common issues and practical solutions:

| Challenge | Best Practice | Outcome |

| Legacy or rigid ERP systems | Use open APIs or middleware for two-way communication | Smooth, non-disruptive integration |

| Data mismatch or inconsistency | Standardize product, pricing, and configuration data upfront | Accurate, synchronized information |

| Siloed teams | Involve sales, IT, engineering, and operations early | Better collaboration and quicker decisions |

| Complex approval workflows | Automate rule-based approvals in CPQ | Faster cycles and stronger compliance |

| Scalability concerns | Choose a flexible CPQ like Cincom that integrates with SAP, Oracle, Dynamics and others | A system that grows with your business |

The Role of Data Synchronization and Workflow Automation

Accurate, real-time data forms the foundation of successful CPQ-ERP integration. When CPQ and ERP stay in sync:

| Focus Area | How Integration Helps | Business Impact |

| Real-time data sync | Updates inventory, pricing, and capacity automatically | More accurate quotes and better decisions |

| Automated approvals | Routes pricing and configuration approvals instantly | Shorter cycles and fewer bottlenecks |

| Order & BOM automation | Creates ERP orders and BOMs directly from CPQ | Faster production starts and fewer errors |

| Cross-team collaboration | Gives all departments access to the same data | Better alignment and operational efficiency |

| Scalability | Supports complex configurations and multiple sales channels | Future-proofed processes |

Driving Operational Excellence with CPQ-ERP Integration

For industrial equipment manufacturers, CPQ-ERP integration is more than a systems upgrade — it’s a pathway to operational excellence. When sales, engineering, and production share one connected workflow, organizations can:

- Move quotes to production without manual steps

- Reduce errors tied to disconnected systems

- Speed up delivery timelines

- Improve transparency across teams

- Offer customers a faster, more reliable experience

Cincom CPQ brings flexibility, scalability, and deep integration capabilities, making it easier for manufacturers to manage complex configurations and evolving product lines while staying operationally efficient.

Struggling with disconnected systems? A unified CPQ-ERP setup can help you fix accuracy issues, reduce delays, and improve customer satisfaction.

FAQs

1. Why is CPQ-ERP integration important for manufacturers?

It ensures consistent data flow from sales to production, improving accuracy, reducing errors, and speeding up quoting and order processing.

2. How does CPQ improve order accuracy?

Approved configurations, pricing, and BOM details transfer directly into ERP without manual re-entry, reducing mistakes.

3. Can CPQ integrate with ERP systems like SAP or Oracle?

Yes. Cincom CPQ integrates with major ERPs including SAP, Oracle, and Microsoft Dynamics.

4. What are the common challenges in integrating CPQ and ERP?

Legacy systems, inconsistent data, and change management are the most common issues, but flexible CPQ tools and standardization help overcome them.

5. What ROI can manufacturers expect?

Faster quote-to-order cycles, fewer errors, improved efficiency, and better customer satisfaction.